Overheating

What is overheating?

Overheating is a term used to describe components that have been subjected to abnormally high exhaust temperature or insufficient cooling.

Causes of overheating:

- Hot shut down

- DPF issues, such as regeneration, resulting in increased exhaust gas pressure and temperatures which leads to overheating of the turbine side of the turbocharger

- Remapping, chipping or over-fueling

Downloads

Signs of overheating:

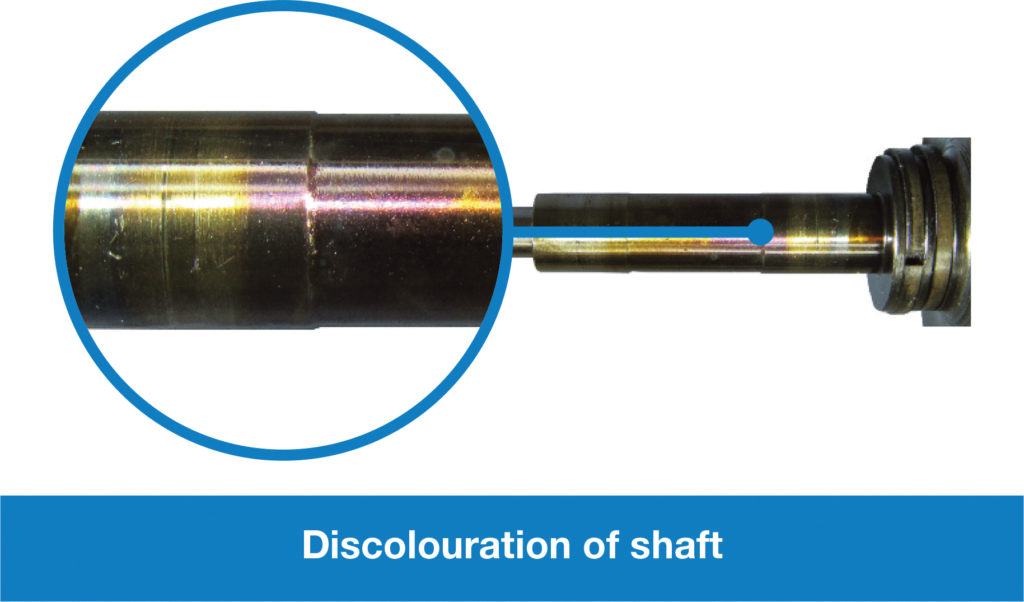

- Discolouration at the hot end of the turbine wheel, spreading along journal bearing area

- “Heat soak” from the turbine side of the turbocharger through to the compressor side, causing discolouration to the turbine shaft and bearing housing

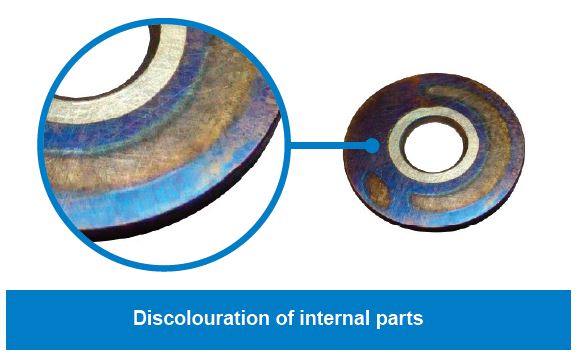

- Discolouration of internal components including thrust washer and flinger; occasionally without evidence of wear

- Collapse (loss of tension) to turbine end piston ring

- Carbon build up in the oil feeds and piston ring area

- Abnormal, excess wear to turbine end piston ring and groove

- Turbine blades appearance being uniformly curved downwards

- Small sections or edges of the turbine blades being fractured/partial loss of blades

Prevention:

- Check the DPF is in good working condition

- Ensure there are no leaks in the cooling lines

- Give the turbocharger time to cool, particularly after long journeys or harsh driving conditions

For further common turbo failure topics, check out our other helps guides

Common turbo failure modes create much discussion between our customers and technical department. To help identify common failures in warranty situations and to provide advice on how to prevent future failures occurring, we have created a series of help guides:

Overspeeding

Foreign Object Damage

Oil Leaks

Oil Contamination

Insufficient Lubrication

REA / SREA

For further information on this or other topics, visit www.melett.com/technical or contact our Technical team via mel_techsupport@wabtec.com